SABIC to demo at OFC 2024 EXTEM resins well suited for micro-lens arrays in co-packaged optics

• SABIC’s EXTEM RH resins support emerging optical technologies by helping enable cost-effective, high-volume production of micro-lens arrays.

• SABIC’s EXTEM RH resins overcome drawbacks of traditional glass and thermosets and other thermoplastic resins by maintaining the dimensional and optical tolerances of complex shapes across a broad temperature range

SABIC, a global leader in the chemical industry, will demonstrate at the 2024 Optical Fiber Communication (OFC) Conference and Exhibition the advantages of its Edison Award-winning EXTEM™ RH series resins for production and assembly of micro-lens arrays (MLAs) in commercial onboard and co-packaged optics. Two demonstrators built by Tyndall National Institute and the Chip Integration Technology Center (CITC) will be featured at the SABIC booth (#1204) during the event.

“As data traffic increases exponentially, driven by AI, IoT and 5G technologies, rapid adoption of opto-electronics has become critical for improving data center bandwidth capacity and energy efficiency,” said Scott Fisher, general manager, Technology, SABIC Specialties. “Optical components for applications like co-packaged optics can be difficult, complex and costly to manufacture and assemble at scale. To address this challenge, we developed EXTEM RH resins, which can deliver key performance and processing capabilities for lens arrays. These resins undertake scalability and manufacturability concerns regarding traditional materials, and open new opportunities to advance the state of the art in optical component design, performance and production.”

Supporting Low-loss Expanded Beam Coupling

Development of photonic integrated circuits (PICs) on silicon or other substrates has enabled compact designs with faster data rates. One challenge is the size disparity between the smaller optical mode field of silicon photonic waveguides and larger single-mode optical fibers.

At OFC 2024, SABIC will demonstrate a promising approach to this issue, which leverages expanded-beam optical interfaces in connections. Beam-expanding optical elements, in this case free-form lens arrays, are installed on each side of the optical connector interface to couple the fiber array to larger free-space beams. Use of expanded-beam coupling can relax lateral alignment tolerances and reduce occlusion effects from contamination like dust particles.

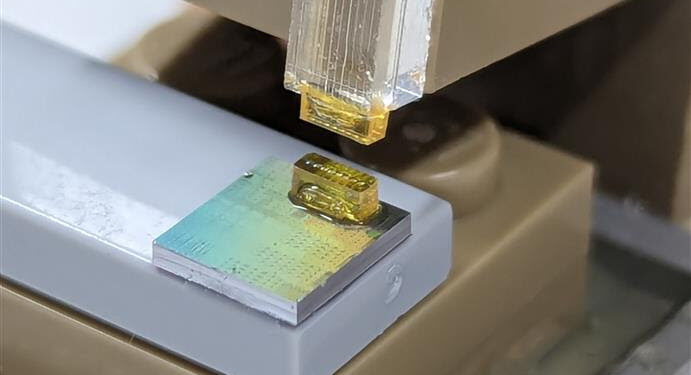

The arrays in this model are micro-molded from EXTEM RH resin which has a glass transition temperature of 280°C and can be injection molded into a wide variety of free-form optical lens designs.

This connector assembly, built by Tyndall, will show how SABIC’s material solutions can help improve the integration of individual optical components in these designs, using established optical fiber connection technologies. Visitors will be able to examine the assembly to understand how optical integration is achieved using optically transparent EXTEM resin with the potential to withstand the extreme temperatures of JEDEC Reflow or surface-mount technology (SMT).

Improving Manufacturing Efficiency

Accelerating adoption of emerging optical technologies requires high-volume, streamlined manufacturing of micro-optics with a relatively low per-part cost – a goal that is not achievable using fused silica or glass. In contrast to these traditional materials, EXTEM RH resins offer several ways to improve the scale and cost-efficiency of micro-optics processing and assembly.

First, micro-molding of EXTEM RH resin can deliver millimeter-size components at a scale of millions of parts with high signal integrity and low optical loss. This capability can help drive faster adoption of cutting-edge optical packaging and coupling technologies in data server backplanes, telecommunications switches, supercomputers and network fabrics.

Further, micro-optics molded from EXTEM RH resin can be aligned with the fiber and a PIC by using optically transparent adhesives before the reflow step to simplify the packaging process.

SABIC’s other demonstrator at OFC 2024 will showcase a process developed collaboratively with CITC that uses an alternative interconnect material – nano silver sintering paste – for the alignment of MLAs with the board. It can replace standard epoxy adhesives, which have drawbacks such as lack of long-term stability and CTE mismatches and require UV-transparent lens materials for curing.

In addition, SABIC will demonstrate the use of complex-shaped lens arrays with total internal reflection, enabling a 90-degree bend of the optical coupling between VCSEL/PD and PIC in a standard MT ferrule connector.

Surpassing Traditional Materials

High-heat EXTEM RH resins won a 2023 Edison Award Gold Medal in the Next Generation Manufacturing category. These advanced thermoplastics provide solutions to the drawbacks of traditional materials for MLAs. Unlike glass and thermosets, EXTEM RH resins offer expanded freedom to design complex lens geometries. Micro-molding avoids the need for secondary operations like grinding and polishing, permitting rapid, high-volume production that can drive down costs.

#modernplasticsindia#indianplasticmagazine#modernplasticsaward#plasticnews #modernplasticsgermany#ginujoseph#modernplastic#plasticindia#plasticrecycling #modernplasticsgobalnetwork#modernglobalnetwork#modernplasticsaward2023 #plasticmagazine#PlasticIndustry#modernplasticsmiddleeast#indianmagazine #modernplasticsamerica#modernplasticsbangladesh#modernplasticsasia#modernplasticsitaly #SABIC #OpticalFiberCommunication(OFC)