Perfect De-Flashing and Dedusting of Duroplast and Thermoplast Components at the Production Rate of the Injection Molding Machine

Less weight, compact design and improved sustainability – a producer of injection molded components has proven that these goals can be achieved economically with high-performance plastic materials. The company is increasingly producing work pieces from duroplast and thermoplast materials that were previously made from metal. Therefore, the capacity for de-flashing these components had to be increased. For this purpose, the customer chose a shot blasting solution from Rösler. The wire mesh belt machine RSAB 470 ensures fast and efficient processing in continuous flow. The swing satellite table machine RWS 1200 is utilized for high-quality, consistent de-flashing of single work pieces. The special dual chamber design of this machine practically eliminates any unproductive idle equipment times.

Ever since ROS GmbH & Co KG was founded in 1926 the processing of plastic materials was always at the center of the company’s activities. Initially named Press plant ROS, the company now has a nearly 100 years old tradition in this field. Today the private business, managed by third generation family members, is a high-end partner for technically demanding injection molded components made from duroplast and thermoplast materials including polyphenylene sulfide (PPS). Product development, tool making, and production take place at the company’s headquarters in Coburg, Germany. An additional manufacturing plant is located in Ummerstadt in the German state of Thuringia. For removing the flashes on the components created by the manufacturing process the company has been working with Rösler shot blast equipment since 2006.

Increase of the de-flashing shot blasting capacity

Jürgen Bär, responsible for planning in the industrial engineering department at ROS in Coburg explains: „The demand for plastic components substituting metal parts, for example in thermo management systems for the automobile industry, has been rapidly growing. In 2021 this forced us to increase our shot blasting capacity at both our manufacturing locations. The plastic components reduce the overall weight of the cars and, therefore, helpto reduce CO2 emissions. In addition, we received large orders for duroplast pre-formed components, among others from a leading manufacturer of garden tools“. After discussions with four suppliers of shot blast equipment the customer chose the wire mesh belt machine RSAB 470 and the swing satellite table machine RWS 1200 from Rösler. Jürgen Bär continues: „Deciding factors for choosing Rösler were our good experience with the shot blast machines we have been using for a long time, the compact, space-saving and sturdy equipment design and Rösler’s comprehensive knowledge in the field of plastic de-flashing. Moreover, we needed the continuous flow shot blast machine quickly. Rösler generously supplied a machine from their customer experience center within a few days“.

Consistent and energy-efficient de-flashing in the tempering frame The flexible high-capacity shot blast machine RSAB 470 at the Coburg location is used for de-flashing of components made from duroplast and the high-performance thermoplast PPS-GF materials. After de-flashing the components undergo a tempering treatment. For this purpose, the components are placed on special frames. Normally the work pieces are placed individually on the wire mesh belt. To streamline the material handling operation and eliminate this time-consuming step, Rösler adapted the standard work piece transport system of the shot blast machine to the workflow at ROS. This re-design now allows placing the raw components on the tempering frames immediately after the injection molding process. The work pieces on the frames are then passing through the shot blast machine for the de-flashing operation and can, thus, be directly transferred to the tempering station. Four turbines, specially designed for plastic de-flashing and placed above and below the wire mesh belt, ensure consistent shot blasting results. This turbine arrangement allows throwing the media consisting of polyamide grains with a diameter of 1 mm onto the work pieces from above and below. Compared to the normally utilized suction air blast systems the turbines, equipped with electric drives, are considerably more energy efficient. Jürgen Bär adds: „Not only our certification per DIN EN 50001 demands a reduction of our energy consumption, but energy savings are also necessary to save costs and for reasons of sustainability“. A blast media flow control with automatic media replenishment ensures that there is always sufficient blast media available in optimal quality. The shot blast machine is equipped with numerous technical features such as the anti-static compound dosing system with automatic compound replenishment, the efficient air extraction from the blast chamber, the dual step parts cleaning system in the outlet zone and the effective blast media cleaning system with screen and air wash separator. All these features guarantee that the components coming out of the shot blast machine are perfectly de-flashed and absolutely clean. Since the plastic materials used at ROS and the polyamide blast media can causeexplosive dust, the shot blast machines were equipped with special, ATEX-compliant filter systems.

Fully automatic and sustainable de-flashing of single work pieces

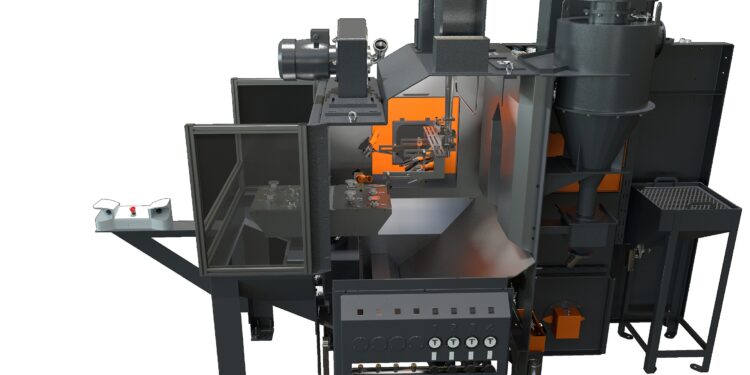

The swing satellite table machine RWS 1200 was installed to increase the shot blasting capacity at the plant in Ummerstadt. It is used for de-flashing components made from PPS-GF and outer dimensions of up to 163 mm. In line with the production cycle of the injection molding machine up to four work pieces are de-flashed simultaneously within a processing time of 40 seconds. The RWS 1200 has two chambers, equipped with four rotary satellite stations per chamber and each satellite holding one work piece. This clever design allows to unload/load work pieces in one chamber, while the work pieces in the other chamber are processed. Unproductive idle times are, therefore, minimized. One energy-efficient blast turbine throws the media onto the work pieces placed on the rotary satellite stations arranged in the shape of a diamond. The satellites are not only rotating but, depending on the work piece geometry, can also be stopped at a certain angle. Work piece areas that cannot be reached by the media thrown by the turbine, are cleaned with special air blast nozzles. This suction air blast system is equipped with pressure control and a vertically moveable nozzle holder ensuring precise de-flashing. In addition to the vertical movement a linear positioning system allows to place the nozzles precisely in front of the work pieces. The nozzles are working in either oscillating or static mode. „To minimize the usage of compressed air, we are working with work piece specific PLC processing programs“, concludes Jürgen Bär.

The RWS 1200 is also equipped with automatic replenishment devices for the blast media and the anti-static compound, an air extraction unit for the blast chamber and a blast media cleaning system.

www.rosler.com

#modernplasticsindia #plasticmagazine #indianmagazine #indianplasticmagazine #modernplasticsaward #ginujoseph #modernplastic #plasticindia #plasticnews #plasticrecycling #modernplasticsglobalnetwork #modernglobalnetwok #modernplasticsaward2022 #PlasticIndustry#rosler