More Efficiency, Digitalisation, Safety and Health With Messer Technology

Cutting and digitalisation solutions increase productivity

The World’s international experts in gouging, cutting and coating will gather this year from September 11th to 15th at the SCHWEISSEN & SCHNEIDEN in Essen – the number 1 meeting point. The cutting experts from Messer Cutting Systems also could not fail to be there. Together with their colleagues from Messer Gas they will be presenting their newest innovations and tried and tested solutions for process optimisation in cutting technology. Efficiency, digitalisation, decarbonisation, safety, health protection – a rich, multifaceted programme awaits the fair visitor on the joint stand B13/23 in Hall 8 on about 530 m².

One of the main attractions from Messer Cutting Systems on the SCHWEISSEN & SCHNEIDEN will be the live demo of the ELEMENT 400. Equipped with oxyfuel and plasma technology as well as two additional marking tools, this thermal cutting machine is suitable for the largest variety of applications with the highest quality demands. The plasma bevel head Bevel-S promises maximum flexibility: complex contours, holes of bevels for weld preparations can be cut effortlessly. What is more, the platform makes high speed marking with proven and robust tools possible for fast and simple identification of various materials.

Optimum conditions for automation in laser cutting technology

Automation is the key to increased productivity and the answer to the challenges of our time, such as lack of skilled personnel and resources. With its newest developments in laser cutting technology, Messer Cutting Systems has created outstanding conditions for successful automated production and is presenting these at the SCHWEISSEN & SCHNEIDEN. Often it is small things which bring the decisive advantage, for example in handling: To be able to handle components better after processing, Messer Cutting Systems have made it possible, for example, to leave micro bridges between the cut parts and the scrap frame. Thus, each part does not have to be picked up separately, rather the plate can be removed as one piece with a loading/unloading system or a shuttle table. This significantly reduces non-productive times. The bridges are so fine that they can be separated easily from the frame later.

Whoever wants to experience the laser cutting machine ELEMENT 400 L in action should also visit the Messer Cutting Systems stand. The experts will switch over to the factory in Groß-Umstadt for a live demonstration, to present the visitor with the remarkable dynamics and newest laser technology for the economical processing of XXL sheets.

Bring orders into production faster and more economically

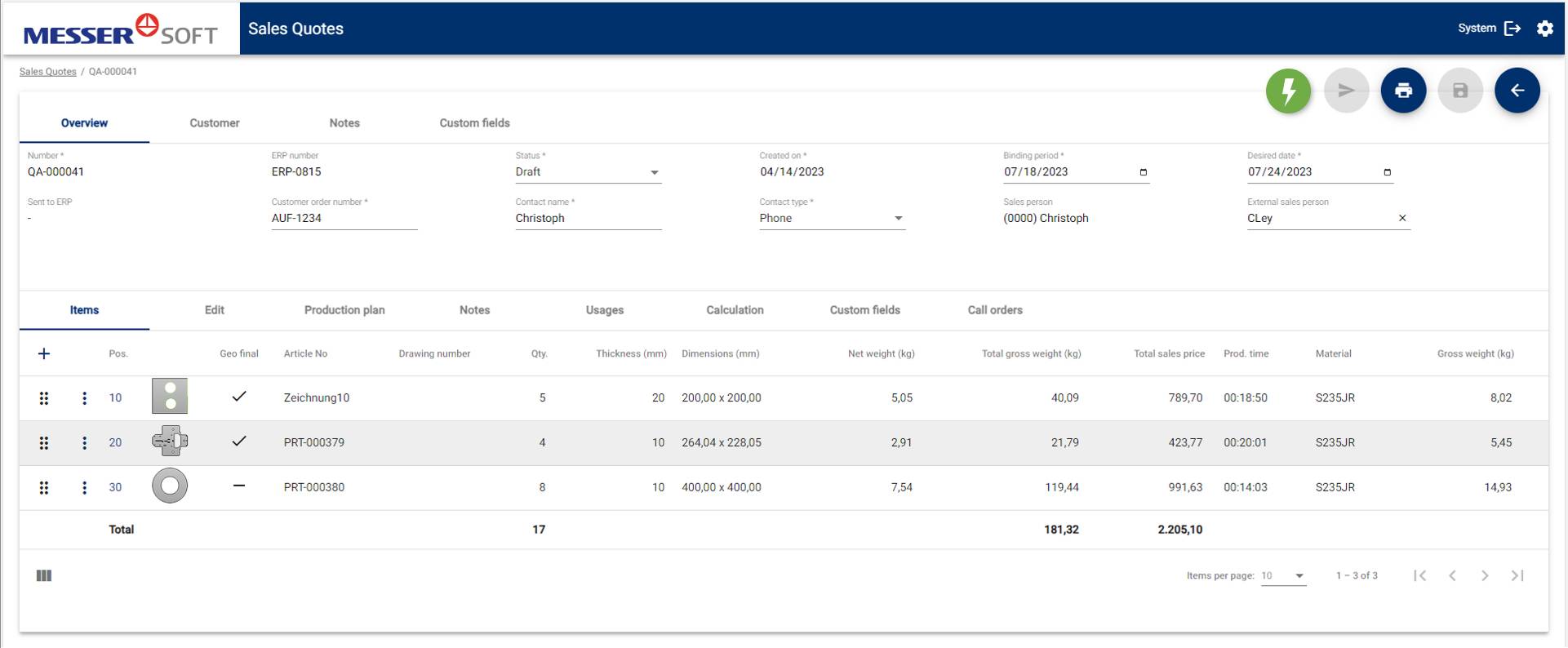

Production planning brings an astonishingly large potential for increasing the efficiency in production significantly, simply and fast. Messer Cutting Systems demonstrates with an exhibition premiere at the SCHWEISSEN & SCHNEIDEN impressively how this can be achieved excellently and with little effort.

With the new version of OmniFab, the software suite for the digitalisation of production, cutting jobs can now be directly placed on the machine from the pre-calculation of customer quotations. With automatic component nesting, the step of CAD/CAM nesting software can be shortened or even completely bypassed. This increases the speed and significantly accelerates the process from submitting quotations to starting the order in production. For some applications this is a revolutionary and new way of working. It is made possible by the direct linking of the software to the Global Connect machine control. With the integration of the CAD/CAM software OmniWin, nesting plans can now also be transferred in real time to the machine. The user saves significant time, especially through the automatic pre-selection of all the parameters necessary for production.

As well as the emphasis on work preparation, the visitor to the fair will also experience on a total of four workstations how the digital solutions for production gain additional competitive advantages and make it easy to enter Industry 4.0.

More safety in oxyfuel technology with S.A.T.

Visitors to the SCHWEISSEN & SCHNEIDEN fair can also experience live and close up the complete world of oxyfuel equipment from Messer Cutting Systems with various combination torch systems for welding, brazing, heating, flame straightening and cutting. With the innovative new development S.A.T. (Safety Advanced Technology), the cutting experts will offer a special live demo highlight. The system contributes proactively to safety of users and workshops in that it automatically shuts off the gas feed should pressure drop, extinguishing the torch.

Sustainability with Messer Gas Solutions

The welding and cutting experts present on their joint stand innovative and proven gas solutions for process optimisation. With new gas mixtures and technologies from Messer, users can increase efficiency, increase safety, and improve their environmental balance.

Sustainable production, health and operating protection and reduction of the CO2 footprint are increasingly the focus today. At the same time economical and productive solutions are as important as ever. This also has its effect on cutting technology and the selection of cutting gasses. HyCut is here a new, powerful and sustainable alternative to conventional oxyfuel application technology. On their joint stand there will be a quite special highlight for this: Messer and Messer Cutting Systems will present live at various stations which possibilities and advantages arise with HyCut.

#MesserTechnology #modernplasticsindia #indianplasticmagazine #modernplasticsaward #plasticnews #modernplasticsgermany #ginujoseph #modernplastic #plasticindia #plasticrecycling #sustainability #modernplasticsglobalnetwork #modernglobalnetwork #modernplasticsaward2023 #plasticmagazine #PlasticIndustry #modernplasticsmiddleeast #indianmagazine #innovations #modernplasticsamerica #modernplasticsbangladesh #modernplasticsasia #modernplasticsitaly