MAAG Group And SIKORA With Joint Booth At Plastindia 2026

The MAAG Group will be participating in Plastindia in New Delhi, India, from February 5 to 10, 2026, presenting innovative product solutions for the polymer, pipe, and hose industries in Hall 06, Booth H6-B2A. For the first time since the acquisition of SIKORA in June 2025, the MAAG Group and SIKORA, manufacturers of measurement, control, inspection, and sorting technology, will be appearing at a joint booth. “Our presence at the trade fair reinforces our strategic planning: We offer polymer processing and quality control systems for our customers,” explains Uwe Kellner, VP Sales EMEIA MAAG Group. Whether pumps, filters, pelletizing systems, pulverizing mills, recycling systems, or measurement and control systems for the manufacture of pipes and hoses or the inspection and sorting of plastic granulate – our systems create decisive added value for our customers.”

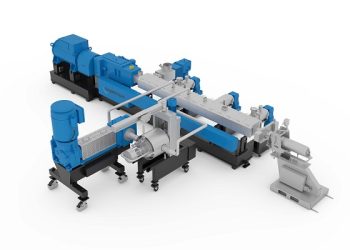

The MAAG Group’s exhibits include the ERF 350 high-performance melt filter and the BAOLI-3 dry-cut strand pelletizer. For recycling applications, MAAG offers continuous melt filters such as the ERF 350, which processes throughputs of up to 3,800 kg/h with a contamination level of up to 16 percent by weight. The melt flows from the outside to the inside through a continuously rotating drum with thousands of conical filtration holes, while impurities such as paper, wood, rubber, or metals remain on the outside of the drum and are continuously scraped off and discharged. A total of four ERF models cover throughputs from 150 to 10,000 kg/h. In addition, four models from the ECO series are available for PET applications with lower levels of contamination, such as production waste.

The BAOLI-3 is a dry-cut strand granulator for compounding and recycling applications. The machine uses core components—including cutting tools and strand feeders—manufactured by MAAG Germany. Three models cover throughput capacities from 20 to 3,450 kg/h, depending on the application and polymer type. Key features include high pellet quality, long service life, low noise level, easy operation, and flexible installation options for different production environments.

At Plastindia, SIKORA will present, among other things, the PURITY CONCEPT V, an offline system for random sampling and analysis of pellets, flakes, and test plates. “The system uses an optical camera to detect contaminants such as black or colored specks and discolorations from 50 µm. The analysis takes less than a minute – including a test certificate and HSV color chart of the detected color deviations,” explains Holger Lieder, Managing Director of SIKORA. The system thus makes a significant contribution to product and quality assurance.

In the field of measurement technology for pipe and hose extrusion, SIKORA also presents the CENTERWAVE 6000. The system measures pipes with diameters from 32 mm to 1,600 mm directly after the first vacuum tank without contact. A continuously rotating transceiver and a powerful processor system use millimeter wave technology to accurately measure the diameter and wall thickness over 360 degrees of the product circumference. This facilitates the centering of the extrusion tools, reduces material consumption, and lowers costs.

In addition, SIKORA presents the X-RAY 6000 PURE, an innovative X-ray system for continuous measurement of total wall thickness, eccentricity, and inner and outer diameter of single-layer hoses and pipes. The system can be flexibly used at various positions in the extrusion line. From the very first day of operation, it enables the wall thickness to be reduced to the minimum permissible value – with considerable material and cost savings.

With their joint appearance at Plastindia 2026, the MAAG Group and SIKORA will showcase their combined expertise across the entire plastics processing value chain. “Our aim is not only to provide customers with first-class machines and systems, but also to support them as a long-term partner with in-depth process expertise,” summarizes Uwe Kellner.

#MAAG #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #Modernplasticsindia