Innovative New System Solves Insert Alignment Challenges with Reliable Mould Coding

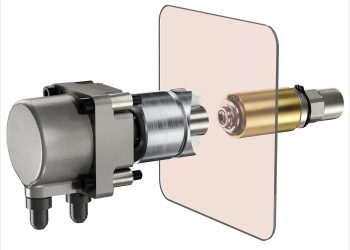

With the new InsertKey Z088/…, HASCO introduces an innovative solution for the clear and unambiguous coding of mould inserts in injection moulding tools — a practical answer to one of the industry’s ongoing challenges. This new system, comprising the sleeve Z0881/… and the bush Z0882/…, reliably ensures that mould inserts can only be installed in one correct position. This not only eliminates the risk of insert mix-ups but also streamlines production workflows and boosts confidence in mould assembly processes.

One of the standout advantages of the InsertKey system is its contribution to process reliability, operational efficiency, and greater standardization in modern mouldmaking. By ensuring that every insert is precisely and consistently positioned, manufacturers can significantly reduce human error during assembly and maintenance. This is especially valuable for companies working with high-cavity tools or multi-variant inserts, where even minor mistakes can lead to costly downtime or defective parts.

The InsertKey’s design cleverly enables the identical, repeatable production of mould inserts. Tasks such as work preparation, storage management for spare parts, and regular maintenance routines all benefit from this standardization — reducing lead times, optimizing inventory, and supporting lean manufacturing goals.

The system’s clever coding method is based on specific rotation within the installation space. Depending on the mould concept, only a single code in the mould frame plate is needed for each insert, with the InsertKey automatically positioning each one correctly. This intuitive approach removes the need for additional markings or manual alignment, saving time on the shop floor while providing robust process security.

Its scalability is another important advantage: by using two InsertKey units, each with eight unique rotational positions, mouldmakers can create up to 64 clearly defined coding combinations (8²). This means the system can easily accommodate a wide variety of tool layouts and cavity numbers, providing maximum flexibility while maintaining a compact footprint. The InsertKey requires no additional installation space or protruding parts, allowing seamless integration even in tight tool designs.

Beyond its technical features, the InsertKey is a practical extension of HASCO’s commitment to delivering standardized, user-friendly solutions that add real value. For toolmakers and processors alike, it means faster set-ups, fewer errors, more reliable spare parts management, and simpler maintenance — all contributing to lower operating costs and improved overall efficiency.

With the launch of the InsertKey, HASCO continues to strengthen its position as a trusted partner for precision mould components. This system is yet another step towards the company’s goal of enabling more efficient, reliable, and future-ready injection moulding processes through smart, practice-oriented innovations that respond directly to the everyday needs of the mouldmaking industry.

#hasco #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #Toolmaking