Choosing the Right Contract Manufacturing Partner: The Growing Importance of Capability, Scalability, and Sustainability

For any medical device OEM, selecting a contract manufacturing organization (CMO) is not a decision to take lightly. In fact, it’s often compared to dating — because the long-term implications of the partnership are just as significant. With stringent FDA and EMA regulatory requirements, long product lifecycles, and intricate product development timelines, switching CMOs mid-stream can be prohibitively expensive and risky. That’s why the first match must be the right one.

At Accumold — a global leader in micro molding — the success of an OEM-CMO partnership hinges on more than just technical capabilities. It’s about finding alignment in values, vision, and capabilities that go beyond part production. It’s about ensuring that the people who will come into contact with your product every day care about it as much as you do. And it’s about choosing a partner with proven capability, scalability, and sustainability to see your project through — from the first prototype to millions of units, delivered with consistency and confidence.

So how should OEMs approach the challenge of finding the right contract manufacturing partner? And what does the ideal CMO relationship look like? Let’s explore those questions through their approach to micro molding and customer collaboration.

UNDERSTANDING THE HUMAN FACTOR IN MANUFACTURING

It’s easy to get caught up in the numbers — cycle times, tolerances, cost-per-part — but those don’t tell the full story. Ultimately, it’s people who make products. And when you’re outsourcing the manufacture of critical components, particularly in regulated fields like medical devices, you’re entrusting your product — and your reputation — to those people.

This is why OEMs should pay attention to the workplace culture, energy, and employee satisfaction at potential CMOs. At Accumold, there’s an emphasis on understanding who is on the floor, assembling, molding, and inspecting your parts. Are they engaged? Do they take pride in their work? Do they collaborate and communicate well?

They answers these questions with transparency. With over 350 employees operating in a state-of-the-art, 130,000 square foot facility that runs 24/7, the company fosters a culture of excellence and accountability. Long-term employment is common — a testament to employee satisfaction and company stability. Visitors often comment on the high energy of the production floor and the cleanliness and organization of employee spaces. These aren’t superficial markers, but instead they reflect a company-wide dedication to quality, order, and doing the right thing — for the customer, and for each other.

MORE THAN JUST MOLDING

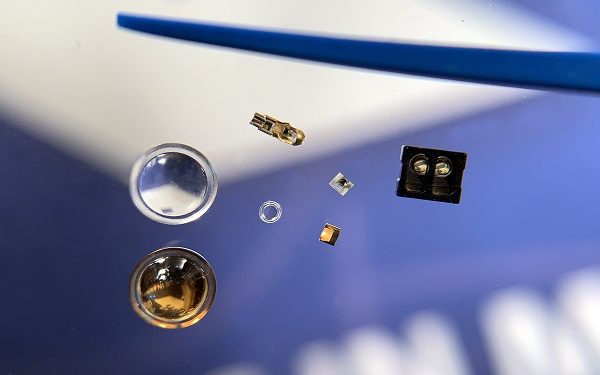

Precision micro molding isn’t merely about making small plastic parts — it’s a discipline that demands mastery across design, tooling, material science, molding, and metrology. Their deep capabilities across all these domains set it apart.

From the outset, they emphasize Design for Micro Molding (DfMM), working collaboratively with OEMs to refine their product designs for manufacturability. The company’s in-house tooling team builds molds that can meet micron-level tolerances. This is not common. In fact, only a small group of companies globally can claim to consistently achieve the precision they deliver.

And it doesn’t stop there. With integrated metrology and validation systems, plus the adoption of micro additive manufacturing (micro-AM) for prototyping and complex geometries, they ensures that even the most advanced parts can be manufactured consistently.

When assessing a CMO, OEMs should ask, “Does this partner have the right technology for our product? Do they have experience in our market? Can they handle the complexity our components demand?”

In their case, the answer is a confident yes. The company’s team doesn’t just make parts — it engineers solutions.

READY FOR GROWTH

A common pitfall for OEMs is selecting a CMO that can make a prototype — but can’t scale. When early-stage development is smooth but volume production falters, programs stall, deadlines slip, and reputations suffer. This is where scalability becomes mission-critical.

Their manufacturing infrastructure is specifically designed for scale. The company runs dedicated high-volume production cells with automation, process control, and repeatable quality baked into every step. Whether the production requirement is in the thousands, millions, or even billions, they have proven it can deliver. This is especially crucial for medical and telecom applications, where demand is sustained and long-term.

Moreover, scalability at Accumold isn’t just physical — it’s also financial. The company’s long-standing operational stability and financial independence means it’s prepared for the long haul. Economic fluctuations, supply chain disruptions, and market volatility are less likely to derail your program when your CMO is well-capitalized and deeply experienced.

It’s important for OEMs to assess whether their CMO has the infrastructure and financial resilience to grow with them. At Accumold, scalability is not an aspiration — it’s the reality, proven every day in production.

SUSTAINABILITY BUILT INTO THE BUSINESS

The word “sustainability” gets thrown around a lot. At Accumold, it’s more than a buzzword — it’s an operating principle. And it’s not just about environmental responsibility, though, that’s certainly part of it.

From an environmental perspective, they minimize waste through precise material usage, energy-efficient practices, and optimized production flows. These efforts not only lower environmental impact, but they also support customer goals for responsible sourcing and lifecycle stewardship.

But sustainability also refers to business sustainability — the ability to remain a trusted, capable partner for the entire product lifecycle, no matter how long. This is especially vital in medical device manufacturing, where product lifespans often exceed 10 years. Having to transfer production mid-cycle due to supplier instability can mean new tooling, revalidation, and regulatory delays. Their 4 decades-long presence and continued investment in people, technology, and infrastructure provide confidence that they’ll be there from day one through year ten and beyond.

As an OEM, you should ask, “Is this CMO built to last? Are they growing sustainably? Do they have a track record of continuity?”

At Accumold, the answers to these questions align with the company’s foundational commitment to long-term, value-driven partnerships.

FIT, ALIGNMENT, AND REALISM

Finally, there’s the matter of “fit”. Not every OEM is right for every CMO — and vice versa. They approach this candidly, evaluating whether a new partnership makes sense early on. Startups, for instance, often come with big ideas but less clarity around manufacturing realities. They invests time upfront to determine whether its services align with the OEM’s needs — and whether both sides are ready for the road ahead.

This approach avoids costly misalignments and sets realistic expectations from the beginning. You want to ask, does the CMO have the technology types that we’re looking at getting into? Do they have experience with the relevant types of products?

The OEM should also consider cultural alignment. Are the people at this CMO driven to do the right thing? Do they have a customer-first mindset? Do they treat each other — and the OEM team — with respect and collaboration?

At Accumold, these qualities are part of the DNA. The team isn’t just skilled — they’re motivated, curious, and committed to innovation on behalf of their customers.

A PARTNERSHIP THAT SCALES

Choosing the right contract manufacturing partner is not just a procurement decision — it’s a strategic investment in the future of your product. And in the high-stakes world of micro molding for medical and high-tech industries, that decision must be guided by more than capabilities alone.

It must encompass an organization’s ability to scale with you, to operate sustainably, and to maintain a team that is not just competent, but collaborative and committed. Accumold exemplifies this model, offering OEMs a partner that is technically equipped, operationally ready, and culturally aligned for long-term success.

In the end, it’s not just about who can mold the part. It’s about who you want molding it — day in and day out — for years to come.

#accu-mold #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#MicroMolding