Arburg Italy: Two Days of celebrations

- Open house: Event on 18 and 19 May 2023 at the subsidiary in Peschiera Borromeo

- Highlights: History and milestone machine to mark 100 years of the Hehl family company

- Big topic: Support for injection moulding plants in Italy

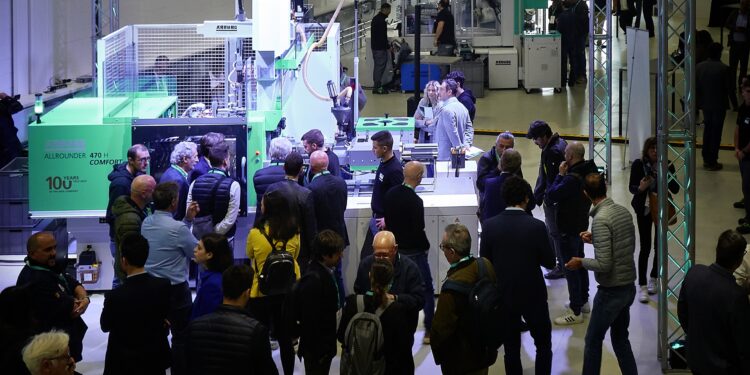

Arburg’s Italian subsidiary in Peschiera Borromeo held its big anniversary celebration to mark 100 years of the Hehl family company. The open house was a real crowd puller thanks to a successful mix of festivities and technical highlights. The focus was on the company’s history, the Allrounder 470 H milestone machine and important information on topics of the future such as digitalisation, the search for young talent and Italian support programmes for machine investment.

Arburg employees and invited specialists presented the information to the visitors as part of an interesting programme. In addition to fascinating presentations and insights into the company’s history, there was also plenty of entertainment and networking. Gerhard Böhm, Managing Director Sales and Service, also came to Italy from the German company headquarters for the two-day open house.

Anniversary and milestone machine

At the start, Raffaele Abbruzzetti, Managing Director of Arburg Italy, and Sales Operation Manager Luca Fasoli, together with Gerhard Böhm, presented the 100-year history of the Hehl family company to the many trade visitors. The detailed presentation of the specially designed milestone machine, the hybrid Allrounder 470 H, was a highlight. During the open house, the machine produced a business card box in a 1+1-cavity mould from Gammaplast Srl. The moulded parts were made of an ABS (BIO Sinkral L 322 Balance BA65) from Versalis, removed by a Multilift Select 8 linear robotic system and placed on an assembly station, where they were finished.

The second injection moulding exhibit was a turnkey system based around a vertical Allrounder 375 V. The compact production cell overmoulded metal inserts with 50 per cent glass-fibre reinforced PA 66/6 to form a two-part “tyre lever” bicycle tool. The material was a single-grade post-industrial recyclate (PIR). The associated Kuka six-axis robot was mounted in a space-saving hanging position and integrated into the Gestica control system.

Digitalisation and Arburg Service

Other highlights included two exhibition areas on the topics of digitalisation and Arburg Service. The new “Action Plan: Energy” was also presented in the “Service Corner”. This plan involves individual energy consultations including energy measurements at the customer’s site and highlights many specific options for optimising energy requirements throughout the entire production process, thereby significantly reducing costs in injection moulding production. The ARS Arburg Remote Service for joint remote maintenance of systems with Arburg specialists was presented on an Allrounder 320 C Golden Edition. In the digitalisation area, guests were able to obtain detailed information about products and services such as the Arburg host computer system ALS and arburgXworld customer portal.

Industrial additive manufacturing

In the additive manufacturing area, Arburg Italy presented the other services it offers with its partner Faberlab and showcased a TiQ 5 3D printer from Arburg’s sister company innovatiQ. The printer produced individual grippers (end-of-arm tool, or EoAT) for robotic systems from carbon fibre reinforced PA. The additive manufacturing of grippers of this kind and other operating equipment on demand is gaining in importance, as decreasing batch sizes mean that the robotic grippers have to be replaced more and more frequently in automated injection moulding and have to be precisely adapted to the respective handling task.

Interesting presentations

The open house was rounded off by a set of content-rich presentations on topics including national and local programmes for promoting machine investments, attracting young talent, Industry 4.0, best practice in mould manufacturing, and the basic principle of TPM (total productive maintenance): a comprehensive approach to plant maintenance and production optimisation. Both days closed with a get-together with drinks, conversation and music.

A weekend for employees

On 20 May, the Italian subsidiary also organised a family day for all employees and their families to celebrate the anniversary. After all, they are ultimately play a major role in Arburg’s great success in Italy. In addition to games and workshops for the kids, there was also a fun magic show that went down well with adults and children alike. This was followed on 21 May by the anniversary sporting event “Maratona del Naviglio”, organised and sponsored by Arburg Srl. The registration fees were donated entirely to good causes. Some of the Arburg employees from Peschiera Borromeo took part in the 10-kilometre run and the half marathon. “100 years of the Hehl family company” – an anniversary for everyone!

Further information about Arburg can be found at www.arburg.com

#modernplasticsindia #plasticmagazine #indianmagazine #indianplasticmagazine #modernplasticsaward #ginujoseph #modernplastic #plasticindia #plasticnews #plasticrecycling #modernplasticsglobalnetwork #modernglobalnetwok #modernplasticsaward2023 #PlasticIndustry #arburg