Perfecting RPET Bottle Production with Advanced Blowscan and Thermoscan Technologies at Drinktec

BMT, a strategic technology partner for packaging, will exhibit state-of-the-art innovations BLOWSCAN and THERMOSCAN, proven to help manufacturers improve PET bottle performance, reduce waste and accelerate development cycles.

At drinktec 2025, BMT (Blow Moulding Technologies), will showcase its cutting-edge hardware innovations, alongside its materials characterisation and simulation services for the global packaging industry.

“At BMT we engineer the virtual world for real-world environmental impact. By making sustainability achievable, we’re helping brands and manufacturers optimise material use, reduce waste, and improve bottle performance,” comments Yannis Salomeia, BMT CEO & Co-founder.

“Join us at drinktec, (C6-531) where we’ll be showcasing our advanced lab tools, BLOWSCAN and THERMOSCAN, designed to unlock data-driven improvements in stretch blow moulding.

“Join us at drinktec, (C6-531) where we’ll be showcasing our advanced lab tools, BLOWSCAN and THERMOSCAN, designed to unlock data-driven improvements in stretch blow moulding.

“Visitors can also explore our signature, the BMT Way, a collaborative workflow that combines data, hardware and technical expertise to streamline PET bottle production.

“Let’s shape a more sustainable future, one bottle at a time.”

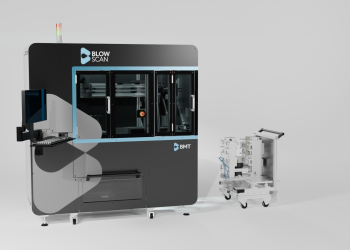

BLOWSCAN – a lab-based, single cavity stretch blow moulding platform

As the packaging industry accelerates use of recycled content, understanding material behaviour during stretch blow moulding (SBM) is essential. rPET and other sustainable materials behave unpredictably, making it harder to ensure consistent bottle performance – driving demand for tools that help R&D teams de-risk production.

At drinktec, BMT directly addresses this challenge directly, showcasing its cutting-edge innovation, BLOWSCAN. This lab-based, single-cavity SBM platform delivers deep, data-driven insight into material performance, preform quality, and bottle development, without disrupting production.

Its modular design allows easy switching between free-blow and mould-blow modes. In free-blow mode, materials such as recycled PET (rPET) or bio-polymers are stretched without mould constraints, making it ideal for benchmarking material behaviour. Mould-blow mode supports rapid prototyping and validation of new geometries, enabling fast iteration during early-stage design and, in some cases, improving material validation rates by up to 20%.

BLOWSCAN uses a batch-fed preform system, no conveyors or hoppers and uses infrared to replicate industrial conditions. It captures key data, including preform temperature, inflation pressure, and blow geometry, enabling robust comparison across materials and machine setups.

“As brands push for lighter, more complex bottles, even small changes can create processing issues. BLOWSCAN helps de-risk early-stage development with quantifiable insights, while supporting site-specific process optimisation,” comments Josh Turner, Head of Materials Characterisation at BMT.

From resin producers and preform manufacturers to brand owners, BLOWSCAN accelerates innovation, improves decision-making, and builds confidence in scaling sustainable packaging.

THERMOSCAN – precision temperature insights for sustainable bottle production

THERMOSCAN – precision temperature insights for sustainable bottle production

Sustainability targets are accelerating the shift to rPET, but recycled materials behave less predictably than virgin PET (vPET), leading to thermal variability and inconsistent bottle performance. Traditional responses, like adjusting oven power, often rely on guesswork, resulting in inefficiencies and quality issues.

At drinktec, BMT will exhibit THERMOSCAN, a lab-based thermal imaging system that provides high-fidelity temperature data for preforms and bottles. By capturing the temperature profile of a successful vPET run, teams can set informed starting points for rPET and use THERMOSCAN to compare and fine-tune heated preforms. This ensures more consistent processing and performance.

THERMOSCAN offers a data-driven way to manage material changeovers, narrowing process windows and reducing reliance on guesswork. It accelerates setup time, improves quality, and supports more controlled, efficient operations.

Rooted in R&D excellence, trusted across the development-to-production spectrum, it helps benchmark thermal behaviour across materials and machines, cutting profiling time by up to 30%. Its value lies in its ability to provide a full temperature profile of the preform, enabling faster, site-specific decisions for sustainable bottle production.

The BMT Way: Measure, Digitise, Execute

Visitors to BMT’s stand at drinktec can also discover the BMT Way – a structured, collaborative workflow that combines hardware, data, and deep technical expertise to streamline bottle development from concept to production, helping teams accelerate innovation, reduce risk, and consistently deliver high-performing bottles.

“It begins by capturing how materials behave in the real world, using tools like THERMOSCAN and BLOWSCAN to gather high-resolution thermal and process data across every stage, from preform to bottle,” explains BMT’s Project Lead, Jude Cameron. “This data replaces assumptions with measurable, repeatable insights. The information is then translated into virtual models to simulate forming and performance, enabling faster, more informed design iteration. “

By digitising this data, teams can explore design, material, and process interactions virtually, validate ideas with confidence, and reduce reliance on trial-and-error. Finally, insights are fed back into production through site-specific process adjustments and quality frameworks, driving consistency, reducing risk, and accelerating time-to-market. Unlike fragmented tools or isolated lab work, the BMT Way closes the loop between design, validation, and execution, helping teams deliver high-performing bottles, faster.

“We’re looking forward to connecting with industry partners and sharing insights into the latest innovations in PET packaging, helping clients de-risk development, improve efficiency, and achieve their sustainability goals,” concludes David McKelvey, Head of Strategic Partnerships and Innovation.

#bmt #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #Drinktec2025