Collaborative Initiative Aims to Transform Fire Safety Testing for EV Battery Casings

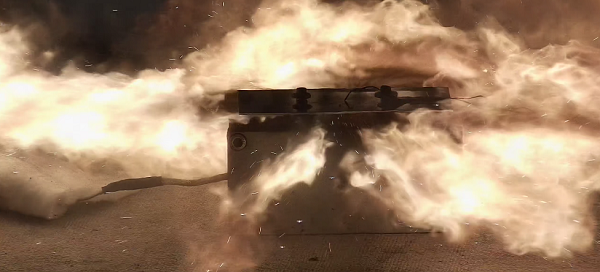

In response to the growing importance of thermal management and fire protection in electromobility, AZL Aachen GmbH is launching a new Joint Partner Project entitled “Thermal Runaway Testing for Battery Casings – Benchmarking Systems for High-Gradient Heating and Hot Particle Blasting.” This initiative focuses on developing and implementing a realistic and reproducible fire testing environment for structural and functional materials used in EV battery housing systems.

Advanced Testing Infrastructure for Real-World Conditions

The project centers around the development and implementation of a new test bench that combines high- gradient flame exposure and controlled hot particle impact – mimicking the complex conditions of thermal runaway events in modern cell technologies such as LFP and NMC. This setup enables systematic benchmarking of materials under stress conditions that reflect actual applications in automotive, but also in other segments like aerospace, where efficient development of safe battery storage systems is essential. Participating companies will not only have access to the final benchmarking results but can also contribute material configurations for testing as part of the project.

Benchmarking Materials and Defining Safety Profiles

Through tailored test profiles, thermal resistance and mechanical integrity of different materials will be compared based on application-specific scenarios. Detailed test documentation, including videos and thermal data, will be provided. The resulting matrix supports materials development, qualification, and supplier evaluation, offering both strategic and technical value.

A Collaborative Approach to a Shared Challenge

Within a predecessor collaboration involving a consortium of 24 leading industry players (including automotive OEMs like Audi, BMW, Tier suppliers, and material producers), AZL ́s team of experts developed an application relevant instrumented test method that allows testing of materials at different flame temperatures and simultaneously measuring the material strength under fire load. In the project more than 50 different materials (metals, plastics, fibre reinforced, coated, compact, sandwich) were tested and benchmarked regarding their specific performance (survival at tensile load and 800, 1000, 1200 °C flame exposure; failure; areal weight; cost per area). The new Joint Partner Project builds on these results, know-how and test infrastructure implemented. It enables participants to pool resources, validate their own solutions, and gain insight into leading alternatives in the market. With more than ten years of experience managing collaborative industry projects, AZL ensures a professional and transparent execution with clear, practical outcomes.

The project will officially kick off on July 15th, 2025. At the initial meeting, partners will align on expectations, present their priorities, and help refine the testing focus. Companies interested in joining are encouraged to request detailed project information or arrange an individual consultation meeting:

#AZL #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #EVInnovation