SMS group supplies open-die forging press to Jiuli Yongxing in China, creating a fully integrated forging line to increase production capacity

- Jiuli Yongxing is expanding its capabilities in forging high-performance alloys to respond to increasing demand from the chemical, aerospace, and energy industries, among others

- Open-die forging press is designed for fully automatic operation

- New forging press and existing SMS radial forging machine will work together to form a fully integrated forging line

- The new open-die forging machine enables upsetting forces of up to 71 meganewtons and forging forces of up to 63 meganewtons

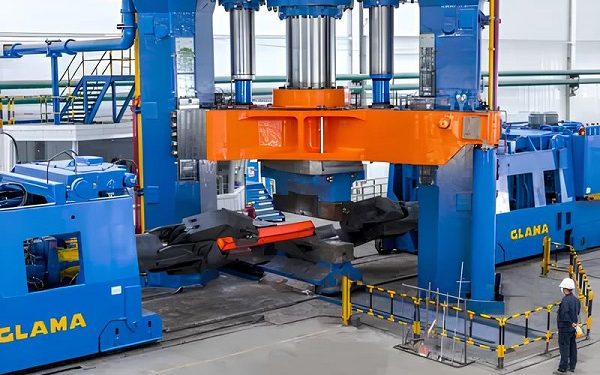

Huzhou Jiuli Yongxing High Performance Metals Co., Ltd., a joint venture subsidiary of Jiuli Hi-Tech, has placed an order with SMS group to supply a 63/71-meganewton two-column push-down open-die forging press. The press will be installed at Jiuli Yongxing’s Huzhou City site in a newly constructed facility, solidifying the company’s strategy to increase production capabilities and further enhance its competitiveness in high-performance industries.

As a leading manufacturer of sophisticated materials such as corrosion resistant alloys, high-temperature alloys, and special stainless steels, Jiuli Yongxing serves a customer base that includes the chemical, aerospace, oil and gas, medical, and energy sectors. With the integration of SMS’s innovative forging technology, Jiuli Yongxing will expand its ability to forge high-alloy austenitic steel grades and nickel-based alloys, meeting the requirements of these markets. Once the new forging press goes into operation, it will enable Jiuli Yongxing to forge a wide range of products, including round bars, plates, and tubes with a weight of up to 23 tons and a maximum length of 15 meters. The press is capable of fully automatic operation, enabled by software solutions that provide a comprehensive materials database and pre-calculated pass schedules, thus ensuring precise process control.

The press will utilize an open-die forging process that improves the microstructural quality of materials through grain refinement, enhancing overall material performance. This process is particularly effective for preparing cast ingots in an upsetting stage, which ensures uniform deformation to the material core. The forging accuracy of approximately 1 millimeter ensures highly precise final products. The pre-deformed ingots will then undergo final forging on Jiuli Yongxing’s existing SMX 900 / 18 MN radial forging machine, also supplied by SMS in 2019. The new press and radial forging machine will form a fully integrated forging line. The forging frequency can reach up to 122 strokes per minute, enabling high productivity rates.

The new press is based on the three-point X-guiding technology, a precision system used in forging presses that employs three guiding points in an “X” configuration to ensure accurate alignment and consistent pressure distribution. The advantages of the three-point X-guiding technology complement those of the enclosed guiding system offering a tailored solution that aligns SMS’s technical expertise with the customer’s production requirements. This integration enhances the precision and efficiency of the forging process, supporting Jiuli’s goal of expanding its production capabilities.

The installed Forgebase Technology Suite software, with its comprehensive materials database, ensures reproducible forging strategies. The software includes pre-calculated pass schedules, enabling the process control and visualization systems to execute reproducible forging processes. The press hydraulic system operates at maximum pressure of 450 bar. Key technical specifications include upsetting forces of up to 71 meganewtons and forging forces of up to 63 meganewtons, ensuring robust and efficient forging capabilities.

This project builds on the longstanding partnership between Jiuli Yongxing and SMS, which began in 2010 with the supply of cold pilger mills. Shen Xiaogang, General Manager from Jiuli Yongxing states, “This new project not only sets a benchmark as a fully integrated forging line with complete process control but also strengthens the long-term cooperation between Jiuli Group and SMS on full lifetime service including engineering, manufacturing, commissioning, training, maintenance and spare parts.”

#SMSgroup #JiuliYongxing #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #ForgingTechnology