Opening new avenues to efficiency with groundbreaking innovations in hot runner technologies

At K 2025, taking place in Düsseldorf/Germany from 8 to 15 October, Oerlikon HRSflow will showcase at Hall 1/Stand C72 its groundbreaking STARgate HRS hot runner technology, which enables precise control of melt injection into the mold cavity through a revolutionary Valve Gate concept. Another new development is the Glow HRS solution, which allows for the direct injection of aesthetic parts in amorphous materials. Systems from the global hot runner specialist will also run live at partner companies, including an injection molding tool for automotive parts that delivers a flawless surface and minimizes secondary operations. Beyond, visitors can expect to see interesting developments in application-specific solutions for multi-cavity systems. These include the Up Nozzle series, which is specifically engineered for compact, tight-space applications with low shot weights, and new solutions designed for luxury and eco-friendly parts in the beauty and personal care industry.

The upcoming K 2025 is organized in close cooperation with Oerlikon HRSflow’s sister brand, Oerlikon Balzers, highlighting the group’s integrated approach to innovation and excellence.

A radical change in injection molding – patented solution

With its newly developed STARgate HRS hot runner technology, Oerlikon HRSflow will present its revolutionary concept for the injection molding industry to the public for the first time at K2025. This technology is a groundbreaking development in the injection molding of PP, PE, PS, and other amorphous thermoplastics. Compared to conventional designs, production, assembly, and maintenance of various components are unnecessary; cycle time is significantly reduced; color changes are easier; and power consumption and pressure loss are reduced. Additionally, the thickness of the back plates can be reduced. STARgate HRS hot runner technology also enables short filling and packing times. At K 2025, this technology will be on display at BMB, an Italian injection molding machine manufacturer (Hall 13/Stand A33), during the production of a bucket. This project was made possible by Oerlikon HRSflow, BMB, the Dutch plastics processors Dijkstra Plastics, Oerlikon Balzers, Piovan and R&D Plastics.

Avoiding halos and weld lines

Another innovation to be unveiled for the first time at K 2025 is the patent-pending GLOW HRS technology, which enables the production of high-quality parts by direct injection, avoiding halos and weld lines. With precise surface temperature control and a compact design, this cutting-edge solution easily adapts to a wide range of applications.

Paint-free, premium automotive parts

At the booth of injection molding manufacturer Haitian International Germany (Hall 15/A57), Oerlikon HRSflow will give a live demonstration of how the FLEXflow HRS servo-controlled needle valve technology can be used to get high-quality automotive parts directly from the mold. This will be illustrated by the manufacturing of a car wheel arch. Developed in collaboration with DNP Group (producer of automotive decoration film printing) and Inevo (mold maker), this joint project impressively demonstrates that the painting of large-format injection-molded parts can be eliminated, minimizing the need for expensive post-processing, even when using recycled materials. Other advantages of FLEXflow HRS technology include quick color changes and reduced material waste.

MULTIflow HRS: New nozzle series and PET thick wall solution now available

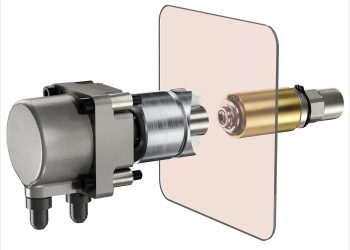

With its compact gate-to-gate pitch (down to 15 mm), the new Up Nozzle series from Oerlikon HRSflow (Picture. 1) is specifically engineered for tight spaces with low shot weights. With a 12-mm nozzle cutout, the series delivers exceptional performance in hard-to-reach gate areas. These features make the series ideal for industries such as beauty and personal care, packaging, beverages, and technical applications.

At their booth, Oerlikon HRSflow will present crystal-clear, eco-friendly parts produced with dedicated hot runner solutions for luxury cosmetic packaging (Picture 2). These components benefit from advantages of the technology, including crystal clarity, significant wall thicknesses of up to 12 mm, and high process repeatability.

Advanced injection moulding technology live

- At the Engel booth (Hall 15/B42-C58), a three-drop system from the Ga series of Oerlikon HRSflow’s Diamond Lux line of hot runner solutions will be demonstrated for producing a rear light concept application. In this process, a decorative foil is back-injected with PLEXIGLAS 8N from RÖHM and then overflooded with PUR. The foil enhances the visual design of the final product. This project is a collaboration between Zechmayer (toolmaker), LEONHARD KURZ (LED and surface design integration), Engel (injection molding machine producer), and RÖHM (material supplier).

- A cable clipper made of PA6.6-GF30 that weighs just 1.2 grams will be produced in a 16-cavity mold at Haitian’s booth in Hall 15/A57. The hot runner configuration consists of 16 Oerlikon HRSflow SA Series nozzles with an open gating system. These nozzles were specially developed for processing glass fiber-reinforced plastics, ensuring perfect cavity filling and outstanding process repeatability.

- BOY’s booth (Hall 13/A43) will feature the injection molding of a conical blood filter using a Jestar medical demonstration mold on a BOY 35E injection molding machine. This process utilizes Oerlikon HRSflow’s Multi Valve Plate (MVP) technology in conjunction with a 16-drop MULTIflow HRS system from the SP series. This technology offers synchronized valve actuation and reduced drop-to-drop spacing, enhancing precision in small weight applications.

#oerlikon #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #K2025