Next-Gen S-Line Robots Deliver Increased Performance and Payload Capabilities

With a clamping power of up to 900 tons, Sepro Group has finished redesigning its high-end robots for use with plastic injection molding machines. The 3-axis S5 Line and 5-axis 5X Line, which have given molders the best automation performance for over ten years, will be replaced by the new S-Line robots, which make their premiere at the K2025 trade show in October.

Three new S-Line robot models have been designed to serve molding machines from 100 to 900 tons of clamping force, with three modular options:

- a basic 3-axis servo-driven configuration

- with additional servo wrist rotations for a total of 5 axes of CNC motion

- or in special application-specific configurations such as a medical version adapted for cleanroom environments

The S Line robots are driven by the new Visual 4 control, making them suitable for the full range of injection-molding automation applications, including multi-machine, multi-robot manufacturing cells.

A highly rigid structure, including the use of cam follower bearings for linear motions, allows the robots to operate at 15% faster speeds for overall better cycle times than were possible with the previous-generation S5 and 5X Line robots. The Y-axis demolding stroke has been extended by to 200 mm (almost 8 inches), increasing the effective stroke length by 22 to 40%, depending on the size of the robot.

A highly rigid structure, including the use of cam follower bearings for linear motions, allows the robots to operate at 15% faster speeds for overall better cycle times than were possible with the previous-generation S5 and 5X Line robots. The Y-axis demolding stroke has been extended by to 200 mm (almost 8 inches), increasing the effective stroke length by 22 to 40%, depending on the size of the robot.

Maximum payload capacity (part plus end-of-arm tooling) has been increased by 20% in the standard models and 40% in heavy-load versions. All this while maintaining the precision and repeatability for which Sepro robots are well known.

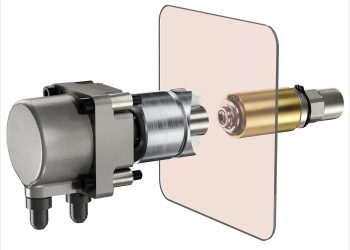

The servo-driven wrist on the new S-Line robots is more compact than previous designs and all 5-axis versions can be equipped with the R3 rotation, which actually adds a 6th axis of motion for greater freedom of movement inside the mold space or outside the molding machine for secondary operations.

The aggressive, modern aesthetic design of the new robots includes multicolor LED lights on the end of the robot mobile. This feature, added in response to frequent customer requests, makes it easy for users to see the exact operational status of the robot even from across the shop floor.

Modular Approach

Beginning in 2021, with the introduction of updated Success Range general-purpose robots, Sepro began implementing a new, simpler modular approach to its products. In addition to delivering manufacturing economies, this approach makes it easy for the molder to consider all the options available and select the ideal robot for any application. Besides 3- and 5-axis robots, the new S-Line family now also includes special configurations – such as units designed for medical and clean-room applications– as options rather than as distinct product lines.

Modularity is extended further by the fact that the new S-Line robots adapt readily to complex cell applications where guarding, conveyors, insert-management, overmolding systems can be supplied as a packaged automation solution.

Sepro plans to continue reconfiguring and simplifying its entire product range and will redesign many of its large robots (for IMMs up to 5000 tons) for introduction in 2026.

#SeproRobots #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #PlasticsAutomation