Innovative Interplay of Plastics Recycling Technologies Showcased at the Global K 2025 Trade Fair for the Circular Economy

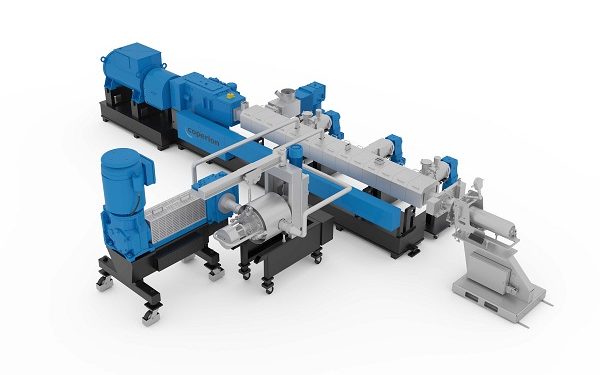

Coperion, together with Herbold Meckesheim, will present their expertise in various plastics recycling applications at this year’s K show in Dusseldorf, Germany (8-15 October 2025). At Booth 9B34 in Hall 9, the focus will be on Herbold Meckesheim’s technologies for mechanical processing of plastics waste. On display will be the new T 150-300 Mechanical Dryer and the SMS 80-200 Granulator. In the Open Area, Pavilion FG/CE07, visitors can witness the seamless interplay of all Coperion recycling technologies. On view will be a Herbold Meckesheim Hydrocyclone Stage, the ZSK FilCo filtration compounder, the ZS-B MEGAfeed side feeder, a Coperion K-Tron K3-V200 vibratory feeder, an S60 single screw feeder and the MechaTron flat bottom feeder. Also on display will be a mobile deodorization unit for reliably removing unpleasant odors from recyclates. In addition to plastics recycling, Coperion specializes in plastic compounding technologies. These core competencies will be on display at Booth 14B19 in Hall 14.

High performance using ZSK FilCo with ZS-B MEGAfeed

In the Open Area, Pavilion FG/CE07, Coperion will exhibit its new ZSK FilCo filtration compounder which enables recyclate filtering and subsequent compounding in one step. In comparison to two-step production lines, the ZSK FilCo handles the product very gently and provides higher quality at significantly reduced energy consumption when recycling post-consumer waste and other highly contaminated polymers. Waste plastics in the form of regrind, fiber pellets, film flakes or agglomerate with no pre-treatment are introduced into a ZSK twin screw extruder where they are melted, homogenized and devolatilized. The melt is then fed through a filter, removing any contaminants. In the subsequent compounding process additives are introduced into the melt prior to pelletizing the compound.

To fully exploit the ZSK FilCo’s high performance, raw materials must be supplied at a constant rate with no intake limits. While this can be accomplished either by pelletizing the waste plastic or regrind, or by using a compacting process, these are very energy-intensive processes and increase both capital and operating costs. In contrast, the ZS-B MEGAfeed side feeder, on display in Pavilion FG/CE07, reliably feeds recycled materials with a bulk density as low as 20 kg/m3 into the ZSK FilCo and other ZSK extruders. This allows for recycling and compounding of lightweight, high-volume fibers and flakes at high throughputs.

Seamless connection of bulk material handling and feeding technology Coperion is an expert in numerous feeding technologies that stand out with their high-accuracy and easy handling. Representative of this expertise, in Pavilion FG/CE07 Coperion will display a Coperion K-Tron K3-V200 vibratory feeder that excels in providing high-accuracy gravimetric feeding particularly for challenging materials, for example where smaller recyclates or flakes are being fed into the extrusion process. For light and fluffy, hard-to-feed materials such as polypropylene or PET plastic film, Coperion will showcase the MechaTron FB (flat bottom) feeder, a gravimetric feeder ideal for high-capacity recycling operations. Also on display is the Coperion K-Tron S60 single screw feeder, another feeder the provides very high reliability.

Coperion developed its ZRD rotary valve especially for plastics recycling processes. Together with the new drive technology, the new design of the gap between the rotor and housing ensures reliable discharge of flakes.

Entire lines from a single supplier

At K 2025, Coperion will demonstrate how its various technologies work together through an all- encompassing 3D simulation. Visitors will gain insights into the operation of a complete system as well as the function of each individual component. All of Coperion’s components and technologies are characterized by high throughput, excellent end-product quality, and exceptional efficiency. For example, Coperion recently successfully commissioned chemical plastics recycling lines at two customer facilities, both capable of processing up to 6,000 kg/h.

Even when recycling PET, processors profit from Coperion’s expertise in engineering complete systems, achieving very good end product quality, and providing high throughputs. Pre-drying the PET flakes is not necessary thanks to the effective degassing in the Coperion process. A few weeks ago, Coperion and Herbold Meckesheim installed the first stage of a bottle-to-bottle recycling plant at Magpet Polymer Pvt Ltd in India. The successful startup of the granulators and washing line marks an important step toward launching the full plant, which is designed to process up to 5,500 kg/h.

Likewise, the benefit of such end-to-end line expertise is evident in the effective removal of unwanted odors. All along the entire recycling process, Coperion offers various solutions for reliably deodorizing post-consumer plastics. Odor removal in mechanical processing, devolatilization in the twin screw extruder, and Coperion’s EcoFresh Silo devolatilization solutions are available to observe. The interplay of these technologies reliably ensures the desired product quality. Coperion recently installed the EcoFresh silo devolatilization at its Recycling Innovation Center. There, customers can thoroughly test various odor removal technologies using actual products under near-production conditions before making an investment. This allows them to ensure that the final process meets all quality requirements.

#coperion #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #K2025