How Bry-Air is Alleviating Cancer Risks With Energy-Efficient PET Drying

The Indian plastic industry is a major contributor to the country’s economy. Coming with a wide range of benefits, plastics find application across diverse industries for their sheer versatility and flexibility. Though it is lightweight, it is inherently highly resistant that is well complemented with high impact strength at the same time. As a result, from automobile to food packaging, healthcare, electrical & electronics, building & construction, wire & cable, etc. almost all industries are seeking plastics for various reasons.

Owing to the increasing utilization of plastic, between April – September 2022, the Indian plastic export stood at US $6.38 billion, and aims to increase the plastic export to reach US $25 billion by 2025. Also, the domestic consumption of plastics too is at its peak, rising year on year. It has grown by 23% and is expected to reach 22 million MT in 2022-23. Hence, it is important more than ever to manufacture plastics of the highest quality that conforms to industry standards for multiple reasons. Plastic processing is a complex process and the industry is continuously on the lookout for energy-efficient and cost-effective solutions. The inability to conduct efficient drying can lead to splash, silver streaking, voids, blisters, gas bubbles, haziness in the final product. Along with this, plastic can also lose its tensile strength and compromise the structure of the product. Similar, is the case in PET drying, a popular form of plastics and having high affinity towards moisture. Drying of PET is one of the most critical steps to ensure superior quality of moulded products.

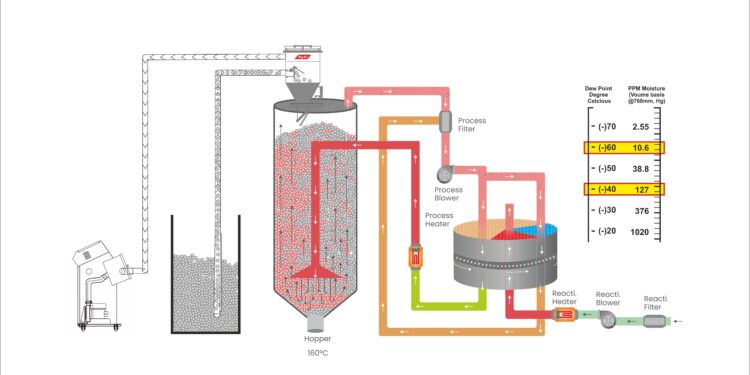

As per the current practice, PET drying is carried out at 160°C temperature with -40° dew point for a residual time of 5-6 hours. Normally, the return air temperature from material drying hopper is 70°C to 80°C. Here, it is important to note that the return air coming out of the hopper needs to be cooled down to achieve a temperature below 45°C for entering the desiccant drying system (honeycomb rotor/ drum). In case the temperature is more than 45°C, it will impact the effectiveness of adsorption. Hence, a cooling coil is installed to compensate the heat. On the other hand, as the material requires a temperature of 160°C, there is a need to add extra energy to the dry air coming out of the desiccant system. This indicates a supply of added energy at both the levels.

Coming with extensive knowledge and continual R&D in desiccant dehumidification and adsorption technologies, Bry-Air Green DrySmart (GDS) delivers same performance of -40°C even at a incoming air temperature of 70°C. Meticulously designed to level up the ‘art of drying,’ it comes with waterless drying ability that is well complemented with honeycomb rotor technology to make it energy-efficient. In the process, it eliminates the use of a cooling coil required to reduce the temperature coming out of the chamber.

At the same time, the air leaving the desiccant rotor is substantially at a higher temperature than that of the air acquired through traditional drying, it requires less amount of energy to reach 160°C. A total of 40% of drying process energy is saved in the whole process.

If the Indian Plastics industry implements the above said desiccant drying process, we can cumulatively save around INR 40 lakh kW energy every year against the 22 lakh metric tons of PET being manufactured annually. This translates to a notional saving of approximately INR 3.2 crore annually for the Indian PET processing industry. Hence, it is the need of the hour that the industry incorporates a coherent PET drying process for ensuring process excellency and optimize manufacturing.

The other important reason for deploying this process is to minimize the formation of acetaldehyde. In the testing process of acetaldehyde in PET, 1 mg of chipped/ peeled PET is heated at 150°C for a duration of 15 minutes which triggers VOC gases and a attached unit of gas chromatography senses the level of acetaldehyde. This chemical is a potential health hazard with the ability to cause cancer. In many countries, maintaining acetaldehyde below the maximum permissible limit is followed very strictly.

If a cooling coil is added to the Bry-Air Green DrySmart (GDS) Dryer, it acts as a Super Dryer, delivers 12 times improved dry air by achieving -60°C dew point. Therefore, the GDS enables a PET processor to select either an energy efficient dryer or opt for a Super dryer and dry their PET at 135°C for a residual time of 3-3.5 hours only thereby reducing the formation of acetaldehyde.

As PET plastics are invariably used in both the primary and secondary packaging, mainly used for water bottles, aerated beverages, juices, liquor, PET aluminum lid cans, jars, trays, etc. installing Super Dryer can keep the level of acetaldehyde within safe limits, making it suitable for safe consumption. Hence, efficient PET drying is the way forward for a resilient product as well as the industry at the same time.

www.grapesdigital.com

#modernplasticsindia #plasticmagazine #indianmagazine #indianplasticmagazine #modernplasticsaward #ginujoseph #modernplastic #plasticindia #plasticnews #plasticrecycling #modernplasticsglobalnetwork #modernglobalnetwok #modernplasticsaward2022 #PlasticIndustry#grapesdigital