ENGEL Brings The World’s Largest Technical Centre Injection Moulding Machine Virtually To K 2025

At K 2025, ENGEL opens the doors to a new dimension of plastics processing. Since some systems are too large even for the largest exhibition stand, the world’s largest injection moulding machine in a technical centre will be experienced as a virtual twin on the ENGEL exhibition stand. In an interactive presentation, ENGEL shows one of the most important trends in automotive construction: the substitution of large-format and painted sheet metal parts through plastic solutions. Using the example of a car roof, the entire production on a duo 5500 combi M with 55,000 kN clamping force is illustrated in a practical manner. A highlight: the clearmelt technology from ENGEL, in which the component is overmoulded directly in the mould with polyurethane (PUR) – an integrated painting that brings processes together and reduces costs.

The Duo 5500 Combi M: A Giant For Automotive Megatrends

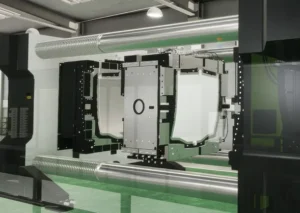

The duo 5500 combi M, which is available for customer trials in the ENGEL technical centre in St. Valentin, is the world’s largest technical centre machine with 55,000 kN clamping force.

It enables the development of components in completely new dimensions. Its exceptionally large mould space with platens of 3.5 x 3.5 metres and a platen distance of 6.6 metres enables the use of moulds with a weight of up to 150 tonnes. Shot weights of up to 42 kilograms are realisable – enabled through injection units with screw diameters of up to 190 mm. This system was specifically designed for the requirements of the automotive industry and technical injection moulding and drives the substitution of metal through plastic further forward. It offers comprehensive possibilities from part and technology development through to the sampling of moulds and parts and thereby underlines once again the role of ENGEL as a pioneer for new technologies.

Interactive Experience At The Exhibition Stand

Visitors can gain a comprehensive picture at the ENGEL exhibition stand of where plastic is used in automotive construction – interactively, from close proximity and with focus on large systems. They can immerse themselves in the machine to discuss the possibilities of large-surface components together with experts from ENGEL. The interactive presentation also impressively presents the ENGEL clearmelt technology.

Clearmelt: Painting In The Mould In Perfection

The ENGEL clearmelt technology integrates the painting process into the injection moulding machine by overmoulding the manufactured part in the mould in a second step with PUR. ENGEL develops the clearmelt process specifically further, also through the close partnership with CANNON, the world’s leading provider for mixing and dosing technologies of reactive processes. This cooperation of two strong, family-led companies bundles decades-long expertise and uses synergies to offer customers forward-looking solutions. The seamless integration of the CANNON clearmelt system into the ENGEL portfolio as well as into the CC300 control from ENGEL ensures high process stability, simple operation and maximum automation. This not only accelerates the production chain, but also improves the overall quality of the end products.

The Clearmelt Competence Centre: Bundled Know-How For Competitive Advantage

In the clearmelt Competence Centre (CCC) in St. Valentin, ENGEL and CANNON bundle for their customers decades-long experience in injection moulding with two decades of clearmelt competence. All services around the flooding with polyurethane come from one source at ENGEL: from process consultation through quotation preparation and the design of the production cell through to complete project handling with comprehensive service performances for the entire production cells. A team of 20 experts supports customers holistically and brings innovative applications quickly and efficiently to series maturity. For this purpose, all duo two platen injection moulding machines with clamping forces from 7,000 to 55,000 kN are available in the CCC.

At the Expert Corner of the exhibition stand, visitors can engage virtually and practically with the ENGEL clearmelt process and the duo machine technology to secure a decisive competitive advantage – entirely in the spirit of “be the first”.

#Engelglobal #interpack #drupa #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #Modernplasticsindia