Efficient Processing of Recyclates with All-Electric Systems and Compact Foaming Innovation at K 2025

At K 2025 ENGEL will be demonstrating how maximum sustainability, cost-efficient production and space-saving system concepts can be successfully combined. The focus is on a production solution for foamed technical parts made from 100 percent post-consumer recyclate. The heart of the exhibit is an all-electric e-mac 220 injection moulding machine which produces thick-walled and robust plastic parts for the construction industry on a minimal footprint. These components offer significant weight savings – in an energy-efficient, precisely foamed and fully automated process.

The manufacturing principle used in this ENGEL production cell is particularly well suited to robust components that are as lightweight as possible and easy to handle, for example for replacing concrete in shafts.

The all-electric e-mac injection moulding machine with a clamping force of 2,200 kN uses ENGEL’s foammelt technology to foam components using a blowing agent. In combination with a specially developed additive mix, this creates a homogeneous, finely celled foam core. The advantage: reduced weight with increased stability. In the application shown, the ENGEL injection moulding cell achieves a weight saving of around 30% with a shot weight of 538 grams, while at the same time increasing the impact resistance of the component by 10%.

A post-consumer recyclate (PCR) is processed, originating from the “Gelber Sack”, collected by PreZero and high-quality reprocessed by EREMA. For the foaming process, an additive and blowing agent mixture developed by Moxietec is used, combined with the Vistamaxx additive from ExxonMobil. The dosing is carried out via a gravimetric system from Movacolor. The Moxietec formulation ensures a particularly homogeneous distribution of the foam structure and is therefore especially suitable for thick-walled components, where conventional physical foaming processes reach their limits.

A post-consumer recyclate (PCR) is processed, originating from the “Gelber Sack”, collected by PreZero and high-quality reprocessed by EREMA. For the foaming process, an additive and blowing agent mixture developed by Moxietec is used, combined with the Vistamaxx additive from ExxonMobil. The dosing is carried out via a gravimetric system from Movacolor. The Moxietec formulation ensures a particularly homogeneous distribution of the foam structure and is therefore especially suitable for thick-walled components, where conventional physical foaming processes reach their limits.

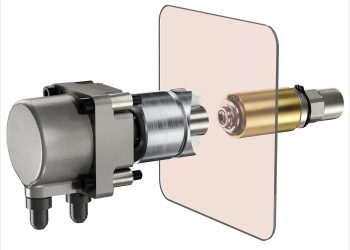

A standard mixing screw from ENGEL ensures a homogeneous melt. It is specially designed for this type of application and optimised for uniform mixing behaviour. In addition, decompression after dosing can be completely omitted, reliably preventing sink marks and air inclusions in the component. This is made possible by a ring non-return valve with a newly developed geometry. Crowned valve wings ensure even greater reproducibility and – in combination with the short-stroke version – significantly faster closing behaviour.

The plasticising unit of this system uses iQ melt control to deliver an optimally prepared melt for foamed recyclates. The digital assistance system iQ melt control analyses the plastification process during sampling and suggests ideal setting parameters for screw speed, back pressure and dosing stroke. In this way, iQ melt control supports consistently high part quality with maximum material efficiency.

A cold runner system additionally supports the desired foaming behaviour. The cycle time on the all-electric ENGEL e-mac using the 2-cavity mould from Moxietec is approximately 120 seconds.

Especially for thick-walled components such as in this application, mould temperature control plays a crucial role. The latest generation of e-temp units operates with just 90 °C water temperature, eliminating the need for separate hot-water piping – which further reduces costs. The digital assistance system iQ flow control actively monitors the temperature control behaviour and regulates it dynamically. In combination with ENGEL’s e-temp devices, this ensures that temperature deviations are detected immediately and automatically corrected. The result is uniform cooling of the entire component – warpage is minimised and dimensional accuracy improved. The system makes a significant contribution to process stability and reduces the energy consumption of temperature control thanks to optimal flow regulation.

The entire production cell is designed to be compact. A servo sprue picker removes the sprue, while an ENGEL viper 12 linear robot takes out the moulded part and places it on a conveyor belt – which is space-savingly integrated into the machine’s safety guard. The automation is fully integrated into the control system of the injection moulding machine and helps reduce cycle times, as iQ motion control independently optimises the movement sequences. At the same time, it also reduces energy consumption. Savings of up to 85% in temperature control are possible. With this application, ENGEL demonstrates how sustainable production, advanced foaming technology and an intelligent cell layout – supported by digital assistance systems such as iQ flow control – can be combined into an economically compelling overall solution. Injection moulding companies benefit from a stable process for demanding recycled material applications, which can be reliably integrated into existing production environments without requiring much floor space.

#Engelglobal #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #K2025