Efficient Physical Foaming for Interior Applications at K 2025

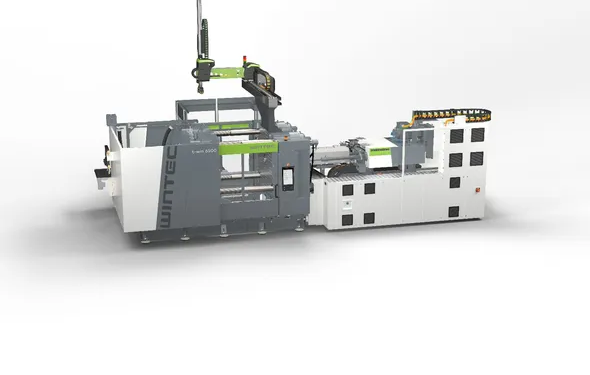

At K 2025, ENGEL is presenting a state-of-the-art manufacturing solution from its WINTEC brand for interior automotive components. At the heart of the exhibit is the t win 6500 twoplaten injection moulding machine with 6500 kN clamping force, equipped with MuCell technology for physical foaming. This combination enables the cost-effective production of a B-pillar trim made of mineral-filled polypropylene in just 50 seconds, while achieving significant material savings.

MuCell works with nitrogen or carbon dioxide, which is introduced into the plastic melt. The screw geometry, specially optimised for MuCell, ensures uniform gas distribution, resulting in a fine cell structure within the mould. The result is a lighter component with outstanding dimensional stability and visible surface quality – ideal for high-end automotive interior parts.

The exhibit part has a shot weight of around 290 grams and is moulded from SABIC’s polypropylene grade F9015. The tool from SIMOLDES demonstrates that complex interior components can be manufactured more sustainably and cost-effectively – without compromising on design. The use of MuCell reduces both weight and material consumption, resulting in a lasting reduction in unit costs.

While ENGEL stands for tailored solutions that meet the highest demands in precision, efficiency and digitalisation, WINTEC offers proven standard solutions with ENGEL DNA. ENGEL primarily targets customers seeking high levels of innovation and customisation, whereas WINTEC delivers cost-optimised, readily available machines for reliable, smart applications. Both brands guarantee high quality, with WINTEC benefitting from ENGEL’s extensive expertise.

The t-win from WINTEC is distinguished by its robust two-platen design. Short-stroke pressure pads enable short cycle times, while a synchronous locking system and servo-hydraulic drive ensure fast and energy-efficient operation. Its high energy efficiency, compact footprint and optimised maintenance access reduce overall operating costs and ensure a fast return on investment.

WINTEC injection moulding machines are equipped with the intuitive C3 control unit, which ensures clear process management with high performance. The new model of a fully integrated viper 20 linear robot handles part removal and relieves the workload on operating personnel. The close integration of robot and machine within a single control system enhances process stability and shortens cycle times by optimising motion sequences.

The digital assistance system iQ hold control supports the optimisation of the holding pressure time during initial process setup. With just one click, it automatically determines the sealing point for the respective component. The result is a significant time saving and optimised cycle times without manual effort, while providing reproducible values.

During ongoing production, the integrated digital assistance system iQ weight control responds in real time to changes in melt viscosity. For each cycle, it analyses the filling behaviour and automatically adjusts the switchover point to ensure consistent part weight. This enables scrap rates to be reduced by up to 85 percent and improves process reliability – a crucial benefit when dealing with fluctuating batch properties.

The ENGEL iQ process observer is also integrated into the production cell. This digital assistance system continuously monitors a wide range of machine and process parameters throughout the injection moulding process, detects deviations at an early stage and automatically provides concrete recommendations for action. As a result, it helps to further increase process stability, ensure consistent part quality and sustainably improve the productivity of the system.

With this fully automated production solution, WINTEC demonstrates what modern interior part manufacturing can look like: reduced material consumption, low energy usage, and consistent performance and quality. Injection moulders benefit from short cycle times, durable machine components, and a compact system solution that can be easily integrated into existing production lines. WINTEC offers efficient plug-and-play solutions with high availability, delivering excellent value for money without compromising performance – a clear competitive advantage for its customers.

#engelglobal#Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #PlasticsIndustry