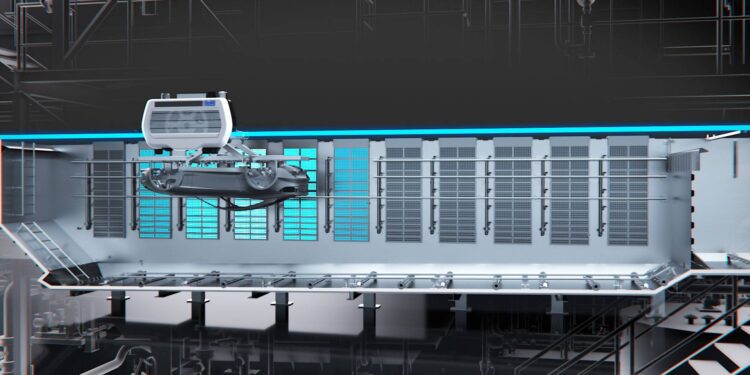

EcoDC MACS: More Power with Less Energy Consumption

Dürr’s new EcoDC MACS rectifier for cathodic electrocoating provides 50 percent more power with the same space requirement, making it possible to design the layout of new plants more flexibly and easily increase existing plants’ capacity. The new rectifier also saves energy and cuts operating and investment costs due to increased efficiency.

Until now, the immersion step of cathodic electrocoating could only be split into a few areas when using conventional thyristor rectifiers. If a rectifier failed, then a big part of the coating current was unavailable, resulting in imperfect coating and an unusable body. This risk no longer exists with EcoDC MACS because Dürr split the previously large thyristor rectifiers into lots of small rectifier modules, each of which supplies voltage to just a small section of the tank. The failure of one rectifier no longer negatively impacts coating quality. Since the smaller units cost just a fraction by comparison, the investment for replacement units is significantly reduced.

Another advantage of the division into many small units is that EcoDC MACS can control small anode groups down to the individual anode. This allows much more precise voltage regulation in the immersion bath and enables optimized voltage profiles – flexibly designed for many body models.

Higher efficiency through silicon carbide semiconductors

Dürr has increased the EcoDC MACS’ efficiency up to 96 percent by replacing the conventional IGBT modules (insulated-gate bipolar transistor) with modern semiconductors made from silicon carbide (SiC). This results in more power with less waste heat and a lower cooling air requirement, translating to energy savings. A sample calculation for a paint shop with 58 bodies per hour proves the difference in effective power because of the SiC semiconductors’ higher operational efficiency is around 45 kW. Assuming 20 hours of production per day, 230 working days per year, and an electricity price of 0.21 euros per kWh, this results in an energy cost reduction of more than 43,000 euros per year in addition to savings from improved network quality and minimal reactive power.

Active harmonics compensation

Another innovation is the linear current consumption made possible by the integrated Active Front End (AFE) technology. The technology balances harmonic currents, which in the worst case, could result in plant shutdowns and stoppages. AFE does away with the need to invest in another compensation system since the power factor increases to ≈1. In addition, the active harmonic compensation guarantees compliance with the legal limit values for the supply voltage quality.

Simplified troubleshooting

Dürr has also optimized data transfer from the rectifier module to the control unit. Data is now transferred via a customary Profinet or Ethernet IP interface instead of through a special ring bus system, simplifying troubleshooting and guaranteeing higher plant availability. A powerful bus system is also an important prerequisite for Industry 4.0 solutions with additional diagnostic options.

Higher voltage for new paints possible

With the new SiC rectifier modules, plant operators are optimally prepared for new requirements arising from future paints possibly requiring higher coating currents or voltages. EcoDC MACS is rated for a higher direct current of up to a maximum of 450 V DC and more current per rectifier mode of up to 120 A DC. The new SiC rectifiers were already installed in two plants where they ensure that the plants function at the optimal operating point and produce the best possible coating results. SiC rectifiers replace the IGBT technology on the market for around ten years but can also be retrofitted in place of conventional thyristor rectifiers.

www.durr.com

#modernplasticsindia #plasticmagazine #indianmagazine #indianplasticmagazine #modernplasticsaward #ginujoseph #modernplastic #plasticindia #plasticnews #plasticrecycling #modernplasticsglobalnetwork #modernglobalnetwok #modernplasticsaward2023 #PlasticIndustry #durr