Achieving Stable Production Through Thermal Insulating Sheets

Optimum heat management for injection moulding tools

Keeping the temperature balance of an injection moulding tool constant is of elementary importance for efficient and resource-saving production. Many factors can influence the parameters in an injection moulding cycle: the ambient temperature in the production rooms, the humidity and the temperature of the injection moulding machine. It is not seldom that the uncontrolled heat loss out of heated injection moulding and compression moulding tools into the platens of the injection moulding machine are responsible for this. It is a case here of keeping the temperature where it is actually needed. This ensures stable production and makes sure that the desired results are obtained. With its extensive portfolio of thermal insulation sheets, HASCO offers the right solution here for every application.

For HASCO – the pioneer of mouldmaking for more than 100 years – heat management is seen as one of the key tasks for the implementation of demanding injection moulding requirements. Back at the design phase, mouldmakers can make an important contributioSn to the fine adjustment of the heat balance in the mould by taking into account special components for the insulation.

Function of the insulating sheet

The task of the thermal insulating sheet is, as the name suggests, to insulate the mould. Heat losses through radiation, convection or contact transfer need to be avoided. For effective and reliable protection, a thermal balance is needed in the injection moulding cycle. Energy is introduced through cooling and possibly the hot runner technology in order to keep the cavity and the melt within the necessary temperature window. The faster and more reliably these temperatures are reached and adhered to, the sooner production can begin.

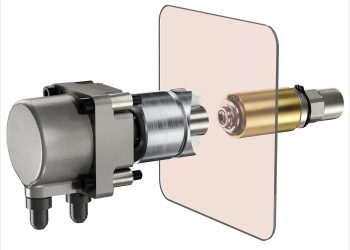

Stress through high pressure

A major factor during the injection moulding process is the pressure of several hundred tons that is repeatedly built up with every mould closure and affects the entire mould structure. The fact that a composite panel like the insulating sheet has to withstand the same loads as a steel panel explains the necessity for the corresponding quality.

HASCO thermal insulating sheets in detail

For this purpose, HASCO provides its customers with the right components. The thermal insulating sheets Z121/…, Z1212…/Z1213/…, Z12120/… and Z12010/…- Z12015… are ideal for thermally insulating the mould from the injection moulding machine. Heat transfer is minimised or excluded completely. In addition, the heat distribution in the actual mould is homogenised. Productivity increases are achieved on the one hand in the fields of part quality and process reliability, and on the other, through high effectivity, resulting from the uniform distribution of the heat in the mould.

Sustainability and energy savings

Indirectly, the thermal insulating sheets help to ensure that the heating elements in the moulding tool do not have to be supplied up to the limit with valuable energy. The reduced load leads to longer lifetimes of the elements. In addition, the defined mould temperature in the mould is reached faster, which accelerates the start of the production. With simple optimisation of design, up to 50 percent energy can, in comparison, be saved, and the process can be made more sustainable.

Technical properties and material composition

The rectangular and square thermal insulating sheets, consisting of glass fibre and synthetic resin material combinations, have good dimensional stability, ensure outstanding thermal properties and have excellent chemical resistance. The application-specific adjustment to the thermal requirements is achieved by the material composition. With an increase in the resin content, the thermal conductivity is reduced, while a comparatively higher glass fibre content increases the compressive strength.

Criteria for selecting the right thermal insulating sheet

The parallelism of the thermal insulating sheet also plays an important role in the selection. It is important that the cavities of the two mould halves run absolutely parallel to each other. Flash formation or poorer ventilation of the mould are undesirable accompanying phenomena if this rule is not adhered to.

And finally, the dimension of each sheet has an influence on the functionality. HASCO thermal insulating sheets are available in thicknesses of 3 to 8.5 mm and are oriented with their dimensions to the common sizes of the platens. When developing the sheets, account was taken in each case of a minus tolerance so that they are not damaged through side stresses.

Customised solutions

In addition to the standard products in various dimensions and designs, HASCO also offers customised solutions for special applications. On the one hand, they refer to the measurements of the products, which are made individually for the customers according to their specifications. For work in a clean room, as in the fields of medical technology or the food industry, the sheets are provided with a PTFE protective coating, which prevents the dissolving of substances during production that would contaminate the article. Apart from that, the possibility of oils and lubricants penetrating the sheet is excluded.

Digital support through the HASCO App

To simplify selection and definition from the wide-ranging portfolio, HASCO provides digital support in the form of an App, which also offers further helpful functions. Here, the mouldmaker or designer can himself determine the surface temperature on the thermal insulating sheet through the input of sheet type and its thickness as well as the mould temperature.

Investment in quality pays off

Summarising, the following selection criteria are of key importance for choosing the right thermal insulating sheet:

- Temperature resistance

- Insulation value or thermal conductivity

- Compressive strength / dimensional stability

- Evenness

- Abrasion resistance

These criteria should be taken into account when selecting the mould insulation. Investment in quality and long service life always pay for themselves through the longer lifecycle of the injection moulding tool.

#HASCO #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #PrintMagazine #PlasticsManufacturing