Hot runner technology for the automotive industry: Minimizing secondary operations in injection molding

At K 2025 Oerlikon HRSflow presented two innovative developments from its range of solutions for the automotive industry: the new, patent-pending GLOW HRS technology and advanced solutions for the low-stress back-injection of films in the production of large parts with high-quality surfaces, significantly reducing costly post-processing.

No halos. Even with direct injection.

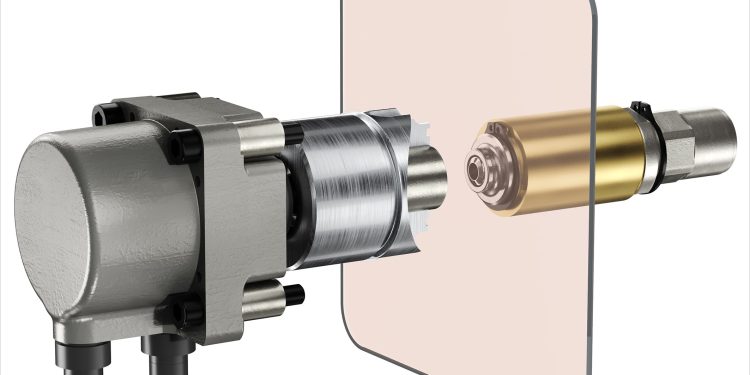

Oerlikon HRSflow’s new GLOW HRS technology is a compact solution for direct injection molding of high-quality parts that prevents halos and enables superior surface aesthetics. Precise control of the surface temperature minimizes the need for post-molding rework and reduces energy consumption, contributing to a more sustainable process. Easy to install and with no impact on cycle time, GLOW HRS technology ensures consistently high productivity. From hoods and tailgates to roofs and smart panels, the system adapts seamlessly to a wide range of automotive applications. To further support customers, Oerlikon HRSflow opens its R&D Test Lab, offering the opportunity to test the technology even with the most challenging polymers.

Achieving premium automotive parts directly from the mold

Using an automotive wheel arch as an example, Oerlikon HRSflow demonstrated the production of paint-free automotive parts using servo-controlled FLEXflow HRS needle valve technology at Haitian International Germany’s K 2025 booth. The electrical system features three drops from the Ma nozzle series and is integrated into an Inevo reverse mold with a vacuum insert. FLEXflow HRS thus enabled precise, low-stress back-injection of recyclable PP onto a decorative PP film insert from DNP Group, which was placed directly in the mold.

The result is a flawless, fully decorated surface that eliminates the need for downstream operations such as transfer, painting, or trimming. The parts leave the mold ready for installation, while their mono-material structure ensures easy recycling without additional reworking. The automotive wheel arch also offers high scratch resistance for long-lasting durability. Moreover, the simple exchange of decorative films allows quick, flexible, and resource-efficient color changes, minimizing waste.

#Konsens #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#PrintPublication #Modernplasticsindia